Introduction

Robust and high-quality data are closely related to a steady experimental environment. Therein, temperature plays a major role and carries the risk of substantially affecting experimental results. Temperature fluctuations are the everyday occurrence in many laboratories. They may derive from staffing, heating, air-conditioning, open windows, waste heat of other instruments, sunlight or seasonal changes. In addition, temperature and humidity depend strongly on the geographic location of the laboratory. Finally, the reader itself contributes to the increased temperature in the incubation chamber and laboratory through its running electronics.

Especially when screening assays in 384- or 1536-well formats, temperature fluctuations may negatively affect temperature-sensitive assays such as binding or enzymatic reactions, luminescence and AlphaScreen®/AlphaLISA® assays. AlphaScreen signal variation is known to be around 8% per 1°C1. Changes in thermodynamic conditions can influence many events including molecular interactions or the efficiency and kinetics of (bio)chemical reactions2. When measuring with a microplate reader, fluctuating temperatures between different reads or even between wells may lead to irreproducible results, poor statistical outcomes, and also potential false positive signals. Experimental precision can be negatively affected by the plate heating up during the measurement.

In general, microplate readers can control the internal temperature from a few degrees above room temperature (RT) to 45°C or higher. The PHERAstar FSX with ‘Advanced Assay Stability (AAS)’ system can match RT conditions or even go below. It can be stably maintained at any temperature between 18 and 45°C. Thereby it provides a steady temperature that is unaffected by external environmental changes. The AAS system furthermore eliminates external airflow to the inside of the reader and helps to keep humidity constant.

Materials & Methods

- 384-well plate, PS, clear (Greiner Bio-One, #781101)

- PBS (Sigma Aldrich, #D8537)

- MicroQCTM Plate (Phosentix)

- PHERAstar FSX with AAS (BMG LABTECH)

Experimental Procedure

Temperature stability monitoring

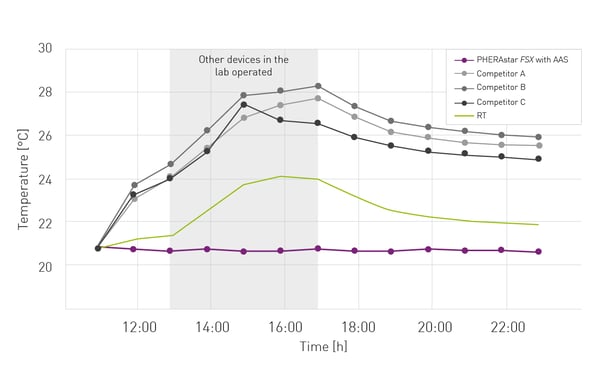

In order to investigate the potential influence of fluctuations in the RT, the temperature in the incubation chamber of all readers was monitored throughout 12 hours (10 AM-10 PM). All three competitor readers remained switched off until the start of the measurement and were set to ‘temperature monitoring’ during the observation period. The PHERAstar FSX with AAS was set to RT (here 20.8°C) half an hour before. Temperature inside the readers was recorded every hour with the respective integrated temperature sensor.

Evaporation studies

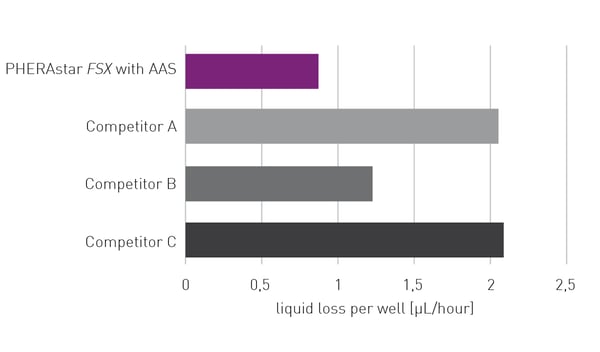

Transparent 384-well plates were filled with PBS (whole plate, 100µL/well) at RT. All competitor readers remained switched off until the start of the observation period while the PHERAstar FSX with AAS was set to RT (here 22°C) half an hour before. Filled microplates were transferred to the readers. The pathlength as a means to determine the filling volume/well was obtained with an absorbance measurement at 990 nm and 993 nm every 15 minutes. The liquid loss per well was calculated from the slope of the descending curves displaying the remaining volume/well in the different instruments.

Instrument cooling time

All readers were heated and maintained at 37°C for 30 min. Competitor readers were then turned off to allow the fastest possible cooling down process. The PHERAstar FSX with AAS was set to 23°C. The temperature during the warm-up, maintenance and cool-down process was monitored with the MicroQC plate (Phosentix) in this experiment for all units, in order to be able to monitor the temperature curve even when the units were switched off.

Results & Discussion

Stable temperature throughout the day

As displayed in fig. 1, RT increases and decreases during daytime, especially when additional devices are operated in the lab. The temperature in the incubation chambers of conventional plate readers follows the RT or even increases as much as +4°C above RT. This greatly reduces the comparability of measurements at different time points throughout the day. The PHERAstar FSX with AAS provides a steady temperature that is unaffected by external environmental changes while the plate reader is operating, providing improved assay stability and more reliable data. Reduced evaporation

Reduced evaporation

Natural self-heating of microplate readers and warming through external fluctuations increase the average temperature in the incubation chamber, leading to increased sample evaporation. Variations in the filling volume of each well may push data variability and cause an overall reduction of data quality and reliability. Thanks to the AAS system the temperature in the PHERAstar FSX can be maintained stably at RT or even below. The possibility to run assays at lower temperatures results in a reduced sample evaporation rate compared to conventional readers (fig. 2). The PHERAstar FSX with AAS is a closed system which allows to further reduce sample evaporation through constant humidity and reduced airflow in the incubation chamber. Thereby it allows to reduce the sample evaporation rate to <1 µL/hour per well compared to conventional readers which partially show rates > 2µL/hour.

Reduced cool-down time

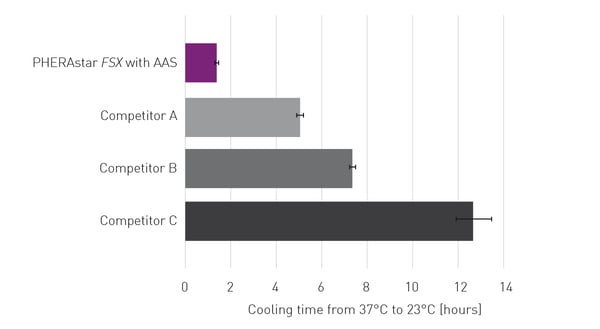

Depending on the plate reader model, it may take some time to cool down to RT after use for an application at an elevated temperature such as 37°C. While some units require over 12 h for the passive cooling process, the PHERAstar FSX with AAS enables active cooling of the unit from 37°C to 23°C in as little as 1:18h (fig. 3).

Conclusion

The PHERAstar FSX with AAS function enables not only to heat the incubation chamber but also to cool it to RT or below. Thanks to its closed system, it also helps to keep the humidity in the unit constant. Accordingly, sample evaporation can be signifi cantly reduced and an overall stable experimental environment can be created individually for each assay. The PHERAstar FSX with AAS thereby provides improved assay stability and hence more reliable, precise and reproducible data.

Moreover, the AAS system enables a significant reduction of the cool-down time when switching from one application at a high temperature to another at lower temperature. This offers many advantages, especially in a multi-user environment with different assay needs.

References

- https://www.urmc.rochester.edu/MediaLibraries/URMCMedia/hts/documents/AlphaScreenPracticalGuide.pdf

- Atkins, P.; De Paula, J.,Physical Chemistry (8th ed.), 2006, W.H. Freeman and Company. p. 212. ISBN 0-7167-8759-8